China Turning Machining Supplier – Custom Parts for Your Projects

Key Attribute

Overview

Your Reliable Source for Rapid Prototypes and Custom Parts

We ensure top-quality, consistent results for prototypes and final parts, produced in-house or with our verified partners.

100+ material options including metals and plastics, over 50 finishing treatments.

Instant quotes available for orders of 1 to 1,000 parts.

Lead times as short as 3 business days.

On-Demand CNC Machining Services

Order custom CNC machined parts for prototypes or production, with fast online quoting and competitive pricing.

CNC Machining: From Prototypes to High-Volume Production

Single-unit CNC prototypes or full-scale production runs (100K+ parts).

Precision machining with tolerances as tight as ±0.01 mm.

Expedited delivery within 5 days.

Comprehensive Strength

Services | We offer a vast array of services including CNC machining with different techniques like turning, 5 - axis and precision machining, mold - making, rapid tooling, injection molding, sheet - metal prototyping, aluminum extrusion, 3D printing, urethane casting, metal casting, rapid prototyping and low - volume manufacturing. We also provide various materials options and surface finishing services in relevant manufacturing processes. |

Capabilities | We are capable of custom - making machined parts. We can handle multiple materials in CNC machining such as aluminum, plastic, stainless steel, brass, copper and foam. There are surface treatment options available for different manufacturing operations to meet various demands of part production. |

| Equipment List | Our advanced equipment ensures precision and versatility across complex machining needs. With 5-axis, 4-axis, and 3-axis CNC machining centers from leading brands like Haas, FANUC, and JingDiao, we handle intricate designs and high-tolerance parts in both metals and plastics. Our EDM, grinding, and metrology tools, including Hexagon CMMs and Mitutoyo testers, guarantee high accuracy and quality. This setup enables us to offer rapid prototyping, mass production, and stringent quality control. |

Industries Served | We serve a wide range of industries, including aerospace, automotive, medical, robotics and automation, consumer products, education, energy, and industrial machinery. |

Quality Control | We have a strict quality assurance system in place. Our quality control processes start from raw material inspection to the final product check. We ensure that every product meets the highest quality standards through continuous monitoring and improvement. |

| Mission & Values | Our mission is to be the leading manufacturing partner for our clients by providing excellent services and products. We value integrity, innovation, teamwork, and customer - centricity in every aspect of our business. |

| Our Vision | We envision a future where we are recognized as the top - choice manufacturing company globally, driving innovation and quality in the manufacturing industry. |

Our Advantage

ISO 9001:2015 Certified

Committed to high-quality services, ensuring project success with 3Es philosophy.

Comprehensive Manufacturing Services

CNC machining, 3D printing, injection molding, and more for diverse needs.

Fast Turnaround

Design completion within hours, enabling quick testing and revisions before production.

Precision Equipment and Expertise

Advanced 3-, 4-, and 5-axis machines, CMM, and material testers ensure tight tolerances.

Product descriptions

Automotive parts are individual components used in the manufacturing and functioning of motor vehicles, including cars, trucks, and motorcycles. These parts range from the engine and transmission to small interior and exterior components, all of which work together to ensure the vehicle operates efficiently and safely.

Automotive parts are crucial in various sectors of the automotive industry. Key applications include:

Powertrain Components: Engine components, transmissions, and drivetrains are essential for vehicle performance.

Suspension Systems: Parts such as shock absorbers, struts, and springs provide stability and safety.

Interior and Exterior Components: Custom parts such as dashboard panels, door handles, and body panels are vital for both aesthetics and functionality.

Safety Systems: Critical components like airbags, seatbelt mechanisms, and brake systems ensure vehicle safety.

Each of these parts plays a pivotal role in the overall performance, safety, and comfort of the vehicle, contributing to a better driving experience.

Different automotive parts require different materials based on their function and performance requirements. Common materials include:

Steel: Used in structural parts like chassis and frames, steel offers strength and durability for heavy-duty applications.

Aluminum: Lightweight and resistant to corrosion, aluminum is often used in engine components and body panels, helping improve fuel efficiency.

Plastic: Versatile and cost-effective, plastics are commonly used for interior components like dashboards and trim pieces.

Titanium: For high-performance and lightweight components, titanium is used in specialized parts such as exhaust systems and suspension components, offering exceptional strength-to-weight ratios.

Each material is chosen for its unique properties to meet specific demands of performance, weight, cost, and durability.

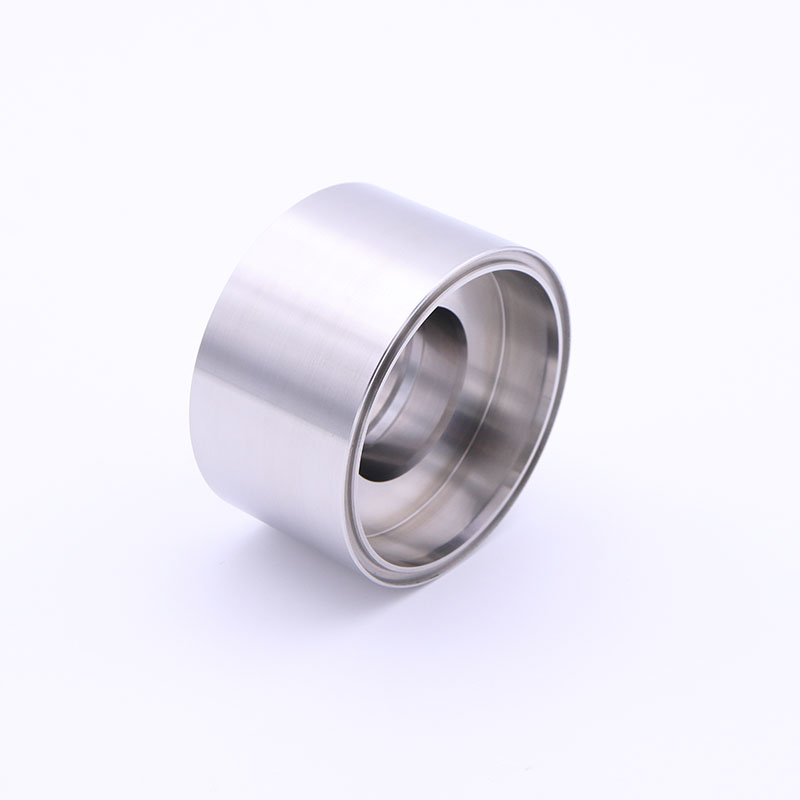

At Xiamen Prime Kunwu Industrial Co., Ltd., we specialize in CNC machining of automotive parts, offering highly customized solutions. The key advantage of CNC machining is its precision and flexibility. Whether you need low-volume production or complex, custom-made parts, our state-of-the-art CNC machines can produce parts with tight tolerances and exceptional quality, tailored to your exact specifications.

Our automotive parts production process follows several key stages:

Design and Prototyping: We create precise 3D models and prototypes to ensure the design meets functional requirements.

CNC Machining: Using 3-axis, 4-axis, and 5-axis CNC machines, we achieve high-precision milling, turning, and drilling.

Surface Treatment: To enhance performance and durability, we apply various surface treatments like anodizing and coating.

Assembly and Testing: Final assembly is completed, followed by rigorous quality testing to ensure the part meets all standards.

Our advanced machinery, such as Haas CNC machines, FANUC, and precision grinders, ensures accuracy and efficiency throughout the process.

Manufacturing automotive parts can be challenging due to the complexity of designs and the need for high precision. Common challenges include:

Tight Tolerances: Achieving ultra-precise dimensions on complex parts.

Material Selection: Ensuring the right material is used for specific functions.

Durability Testing: Parts must withstand real-world conditions like high stress, heat, and wear.

Our solution is a combination of state-of-the-art equipment, experienced engineers, and rigorous testing protocols that ensure each part meets the highest standards.

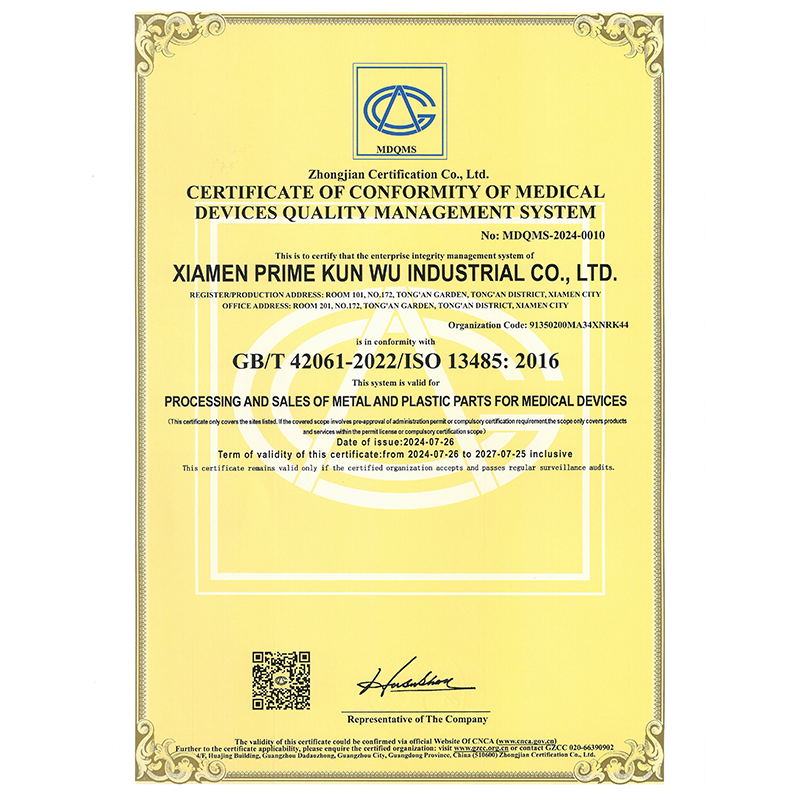

We take quality control seriously. Our ISO 9001:2015 and IATF 16949 certifications demonstrate our commitment to delivering reliable, high-quality automotive parts. Our stringent quality control processes, including regular inspections and material testing, ensure consistent performance and long-lasting durability of each part we produce.

Certifications

| Certifications | GB/T19001-2016/ISO9001:2015 Certification,GB/T 42061-2022/ISO13485:2016 Certification, IATF 16949:2016 Certification |

IATF 16949:2016

GB/T19001-2016/ISO9001:2015

GB/T 42061-2022/ISO13485:2016

Customer Reviews

— John Davis, Purchasing Manager, AutoTech Solutions

"They provided precise machining services for our automotive parts, enhancing product performance and durability. Timely delivery and strong technical support. A very professional team!"

— David Brown, R&D Head, PrecisionDrive Ltd.

"We faced challenges with complex precision parts, and the company provided technical optimization solutions with remarkable results. Highly appreciate their expertise!"

FAQs

Automotive parts refer to the components and systems that make up a vehicle, including engine, transmission, suspension, and electrical systems.

Automotive parts directly affect the vehicle's efficiency, safety, and longevity. High-quality parts ensure optimal performance and reduced maintenance costs.

Precision automotive parts ensure proper fit, function, and durability, reducing the risk of failure and enhancing vehicle safety and performance.

Yes, we offer custom automotive parts machining to meet the unique specifications and requirements of different vehicle models and performance needs.

Gallery

Automotive parts and services

Automotive parts service

Automotive parts

CNC automotive parts

CNC machine automotive parts

Injection moulding automotive parts

Machining automotive parts

CNC automotive parts

Contact Info

Mr. Brook Lin

Job Title: Sales manager

E-mail: [email protected]

Mob/WhatsApp:+86 13599927066

Wechat:+86 13599927066 Skype:+86 13599927066

Country/Region: China (Mainland) Province/State: Fujian

Operational Address: Building 172, Tongan Industrial Zone, Tongan Area, Xiamen, Fujian, China (Mainland) Zip: 361100