Services

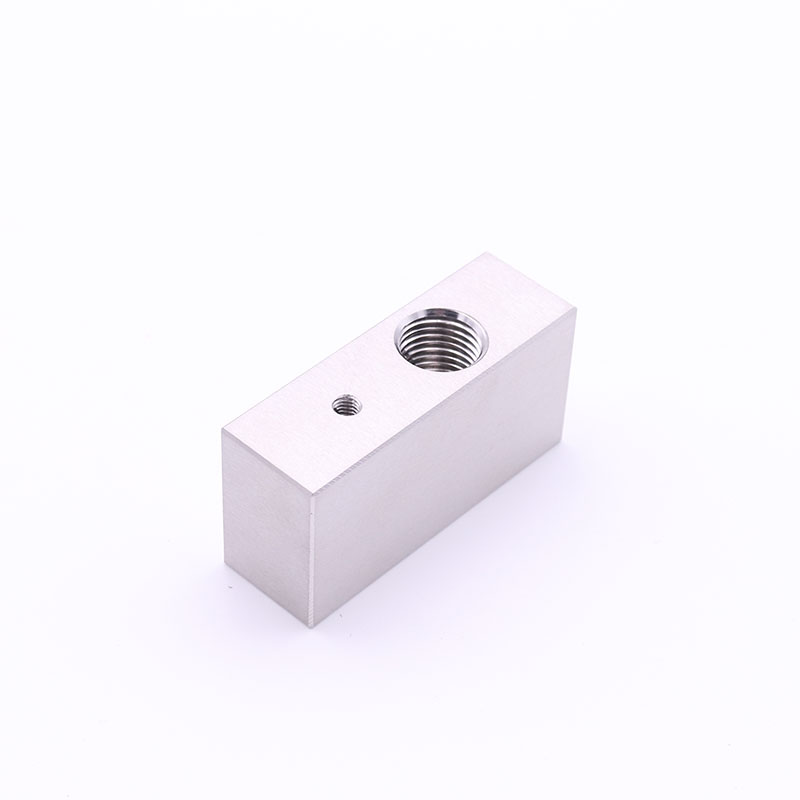

| CNC Machining: Precision CNC machining services for various materials including metals and plastics. We offer milling, turning, and other machining operations to create high-quality custom parts. Parts Finishing: A range of surface finishing options to enhance the appearance and functionality of machined parts. |

Custom Machined Parts | We can produce custom parts according to your specific design requirements. |

CNC Machining Material | Work with a wide range of materials such as aluminum, steel, titanium, plastics, etc. |

Surface Treatment | Offer various surface finishing treatments like anodizing, plating, painting to achieve different aesthetic and functional results. |

Industries Served | Automotive Prototyping: Provide prototyping solutions for automotive components and systems. Medical Device Prototyping: Support the development of medical device prototypes. Product Development Prototyping: Assist in creating prototypes for various product development projects. Industrial Design Prototyping: Offer prototyping services for industrial design concepts. |

Applications | Prototype Concept Models: Create initial models to visualize and test design concepts. Visual Presentation Prototypes: Used for presenting and communicating design ideas. Functional Working Prototype: Build prototypes that can perform actual functions for testing and validation. Design Engineering Verification: Verify the design and engineering aspects of a product through prototyping. Low-Volume Manufacturing: Produce small quantities of products for initial market testing or specialized applications. |

Quality Management | We have a comprehensive quality assurance system in place. This includes strict inspection procedures at every stage of the manufacturing process, from raw material inspection to final product testing. We use advanced inspection equipment to ensure that all products meet or exceed industry standards. |

| Inspection Equipment | We utilize advanced inspection equipment such as coordinate measuring machines (CMM), optical profilometers, and hardness testers to ensure the accuracy and quality of our products. |

| Mission & Values | Our mission is to provide innovative and reliable manufacturing solutions to help our clients succeed. We value quality, innovation, customer satisfaction, and teamwork in everything we do. |

| Our Vision | To be the global leader in rapid prototyping and custom manufacturing, known for our exceptional quality, speed, and customer service. |

Fast Turnaround

We offer quick production times to meet your tight deadlines.

High Quality

Ensure the highest quality of products through strict quality control measures.

Customization

Tailor our services to your specific needs and requirements.

Technical Expertise

Our team has extensive knowledge and experience in various manufacturing technologies.

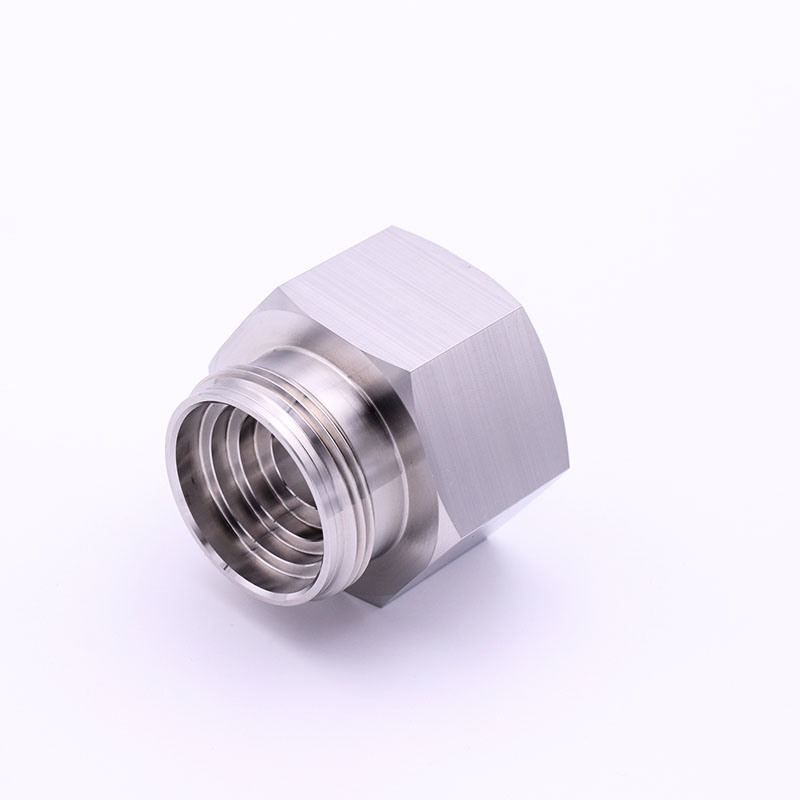

Medical Parts: Precision Engineering for Healthcare

What Are the Types of Medical Parts?

Medical parts encompass a wide range of components essential for the healthcare industry, including:

Implants: Devices implanted in the body, such as joint replacements and stents.

Instruments: Surgical and diagnostic tools like scalpels and endoscopes.

Devices: Equipment for monitoring or treating patients, such as infusion pumps.

Prosthetics: Artificial limbs or body parts.

Consumables: Single-use items like syringes and gloves.

Connectors and Tubing: Essential for fluid and air transfer in various applications.

Electronics: Sensors and circuit boards critical for device functionality.

Software: Embedded systems for controlling devices and analyzing data.

Applications Across Industries

Medical parts are integral to various industries, including:

Healthcare: Critical in surgeries and diagnostics, ensuring patient safety and effectiveness.

Orthopedics: Implants and prosthetics aid in rehabilitation and mobility restoration.

Dental: Implants and tools for dental procedures improve patient outcomes.

Emergency Services: Essential equipment for emergency care and rapid response.

Each industry relies on medical parts to enhance performance, reliability, and patient care.

Materials for Production

The production of medical parts involves various materials, each suited to specific applications:

Titanium: Known for its strength and biocompatibility, ideal for implants and surgical instruments.

Stainless Steel: Used for surgical tools and implants, offering corrosion resistance and durability.

Plastics: Common in consumables like syringes and connectors, providing lightweight and cost-effective solutions.

Ceramics: Used in implants for their hardness and biocompatibility.

Selecting the right material is crucial for performance and safety in medical applications.

Advantages of CNC Custom Machining

At Xiamen Prime Kunwu Industrial Co., Ltd., we leverage CNC custom machining to create tailored medical parts.

Our advantages include:

Precision: High accuracy in manufacturing ensures parts meet stringent specifications.

Flexibility: Ability to produce complex geometries that standard processes cannot achieve.

Efficiency: Reduced lead times and costs through optimized manufacturing processes.

We work closely with clients to customize solutions that align with their specific needs.

Advanced Manufacturing Processes

Our advanced manufacturing process includes:

CNC Machining: Utilizing high-precision machines for cutting and shaping materials.

Surface Treatment: Enhancing durability and biocompatibility through processes like anodizing and coating.

Quality Control: Continuous monitoring during production to ensure standards are met.

Key equipment used includes CNC milling machines, lathes, and inspection tools.

Technical Challenges and Solutions

Producing medical parts comes with technical challenges such as:

Tight Tolerances: Ensuring parts fit precisely to avoid complications.

Material Properties: Managing variations in material characteristics.

Our solutions include advanced simulation software and robust testing procedures to mitigate risks and ensure quality.

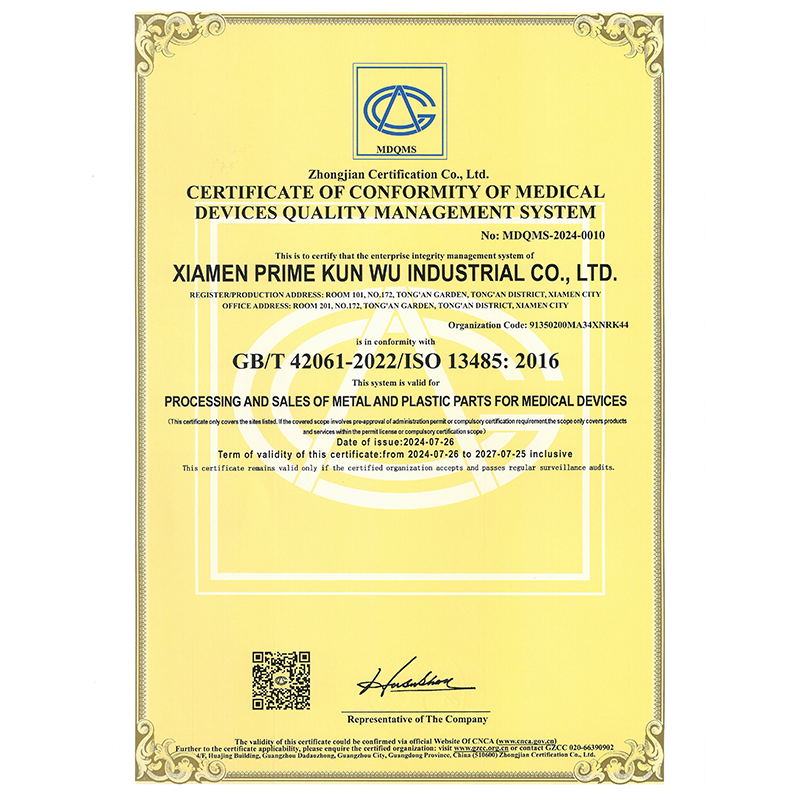

Quality Control and Certifications

Our quality control system adheres to international standards, ensuring stability and consistency in our medical parts.

Key certifications include ISO 13485, which emphasizes our commitment to quality management in the medical device industry.

This framework guarantees that our products consistently meet customer and regulatory requirements, enhancing trust and reliability.

| Certifications | GB/T19001-2016/ISO9001:2015 Certification,GB/T 42061-2022/ISO13485:2016 Certification, IATF 16949:2016 Certification |

GB/T19001-2016/ISO9001:2015

GB/T 42061-2022/ISO13485:2016

—Joseph, Engineer, DEF Electronics.

“Our collaboration with your company on a new electronic component went very smoothly. Your technical support team provided significant help in design optimization and material selection, leading to impressive results.”

—Sarah, Quality Manager,GHI Aviation.

“In the machining of aviation parts, safety and reliability are crucial. Your company demonstrated a high level of professionalism, ensuring that every step from design to delivery was reassuring.”

1. What are medical parts?

Medical parts are components used in the manufacturing of medical devices, including items like surgical instruments,

diagnostic equipment, and implants.

2. How are medical parts made?

Medical parts are made using processes like CNC machining, injection molding, and 3D printing to ensure precision,

safety, and quality standards.

3. What materials are used for medical parts?

Common materials for medical parts include stainless steel, titanium, silicone, and various plastics, selected for their strength,

biocompatibility, and durability.

4. Why are medical parts critical in healthcare?

Medical parts are essential for ensuring the safety, functionality, and reliability of medical devices, directly impacting patient

care and treatment outcomes.

5. How do I choose a supplier for medical parts?

Choose a supplier that complies with industry standards like ISO 13485, offers high-quality materials, and provides reliable

manufacturing capabilities for medical parts.

medical equipment suppliers

medical machinery manufacturers

medical parts manufacturing companies

Mr. Brook Lin

Job Title: Sales manager

E-mail: [email protected]

Mob/WhatsApp:+86 13599927066

Wechat:+86 13599927066 Skype:+86 13599927066

Country/Region: China (Mainland) Province/State: Fujian

Operational Address: Building 172, Tongan Industrial Zone, Tongan Area, Xiamen, Fujian, China (Mainland) Zip: 361100