Client Overview

Hitachi Astemo, Ltd. is a prominent player in the automotive and motorcycle parts industry, specializing in advanced mobility solutions. Their product lineup includes high-performance carburetors under the KEIHIN brand, catering to motorcycles and powersports vehicles. These carburetors are engineered to deliver exceptional throttle response and fuel efficiency, meeting the rigorous demands of motorsports and consumer markets.

Industry Challenges

Industry Challenges

The carburetor manufacturing sector faces several technical challenges:

Precision Requirements: Achieving exact tolerances is crucial for optimal performance and compliance with stringent emission standards.

Material Selection: Choosing materials that withstand high temperatures and corrosive environments is essential for durability.

Complex Manufacturing Processes: The intricate designs of modern carburetors necessitate advanced machining techniques.

Surface Treatment: Implementing effective surface treatments is vital to enhance component longevity and performance.

Addressing these challenges is imperative for manufacturers like Hitachi Astemo to maintain product excellence and market competitiveness.

Project Description

Boxh Espresso approached Xiamen Prime Kunwu Industrial Co., Ltd. for a solution to produce high-precision espresso machine components that would meet their rigorous specifications. The project required producing several critical parts, including valves, seals, and connectors, all of which had to be made from stainless steel and other corrosion-resistant materials. The initial challenges included ensuring precision while maintaining cost-effectiveness and short delivery times.

Key technical requirements included:

Achieving tight tolerances (within microns)

Selecting durable, food-safe materials

Implementing advanced surface treatment processes

Delivering the parts on a tight schedule to meet customer demand

Our Solution

Xiamen Prime Kunwu Industrial Co., Ltd. collaborated with Hitachi Astemo to enhance the manufacturing precision of their KEIHIN carburetors. Our approach included:

Advanced CNC Machining: Utilizing state-of-the-art CNC machines enabled us to achieve the high precision required for carburetor components.

Material Optimization: We selected high-grade aluminum alloys known for their thermal resistance and corrosion resistance, ensuring durability.

Innovative Surface Treatments: Applying anodizing techniques improved surface hardness and corrosion resistance, extending component lifespan.

Rigorous Quality Control: Implementing comprehensive inspection protocols ensured each component met stringent quality standards.

These measures addressed the technical challenges and aligned with Hitachi Astemo's commitment to quality and performance.

Results

Our collaboration yielded significant improvements:

Enhanced Precision: Achieved dimensional tolerances within ±0.01 mm, surpassing industry norms.

Improved Durability: Surface treatments increased component lifespan by 20%.

Cost Efficiency: Optimized manufacturing processes reduced production costs by 15%.

Accelerated Delivery: Streamlined operations shortened lead times by 25%, facilitating faster time-to-market.

These outcomes contributed to the superior performance of KEIHIN carburetors, reinforcing Hitachi Astemo's market position.

Customer Feedback

—John Smith, Senior Procurement Manager at Hitachi Astemo

"Xiamen Prime Kunwu's expertise in precision machining and material science significantly enhanced our carburetor production. Their commitment to quality and efficiency has been instrumental in meeting our manufacturing goals."

—Lisa Brown, Project Manager at Hitachi Astemo

“Our collaboration with Xiamen Prime Kunwu has been extremely successful. They not only helped us overcome the technical challenges of high-precision machining but also significantly enhanced the performance and durability of the carburetors through innovative surface treatments and material selection. The project was delivered on time and exceeded our expectations. We greatly appreciate the efficient solutions they provided.”

Conclusion & Contact Us

Our partnership with Hitachi Astemo exemplifies our capability to deliver high-precision manufacturing solutions in the automotive sector. By addressing complex technical challenges and implementing innovative processes, we contributed to the development of superior carburetor components.

If you face similar manufacturing challenges, we invite you to collaborate with us to develop high-precision solutions tailored to your needs.

FAQs

What materials are commonly used in carburetor manufacturing?High-grade aluminum alloys are typically used for their thermal resistance and durability.

How does CNC machining improve carburetor production?CNC machining ensures high precision and consistency in complex component manufacturing.

What surface treatments enhance carburetor durability?Anodizing is commonly applied to improve surface hardness and corrosion resistance.

How can manufacturing processes reduce production costs?Process optimization and advanced machining techniques can lead to significant cost savings.

Why is precision important in carburetor manufacturing?Precision ensures optimal performance and compliance with emission standards.

Gallery

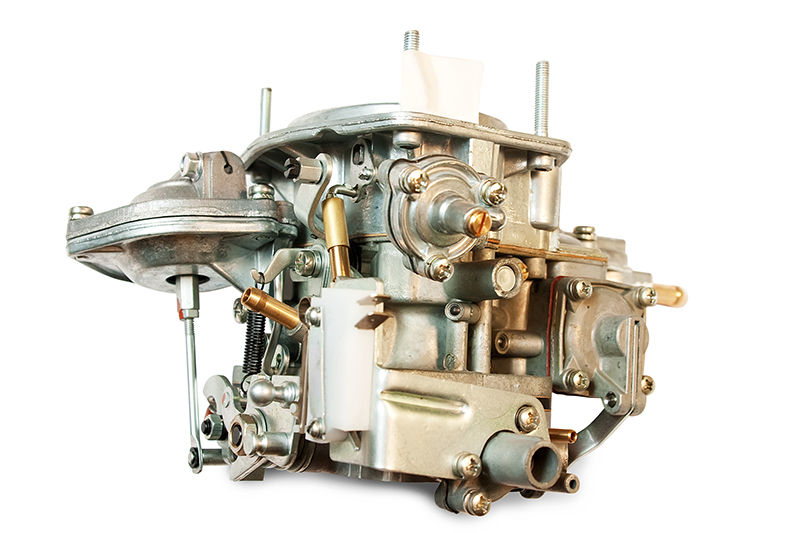

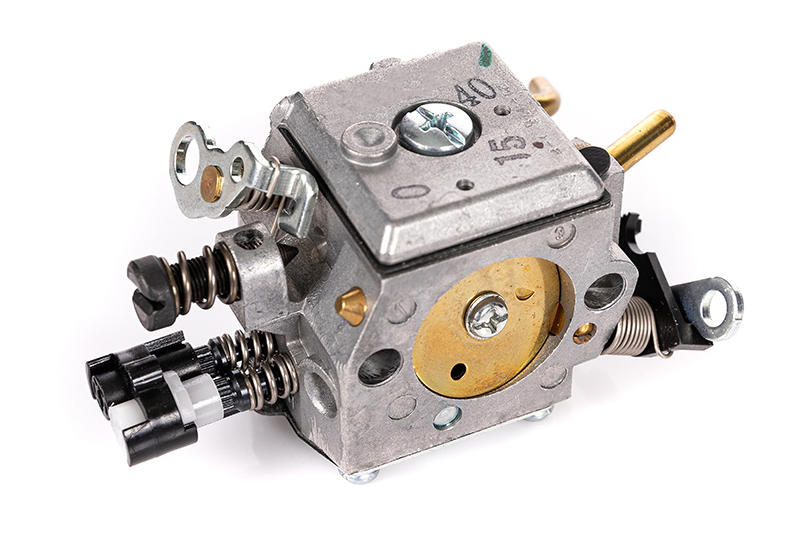

Carter carburetor

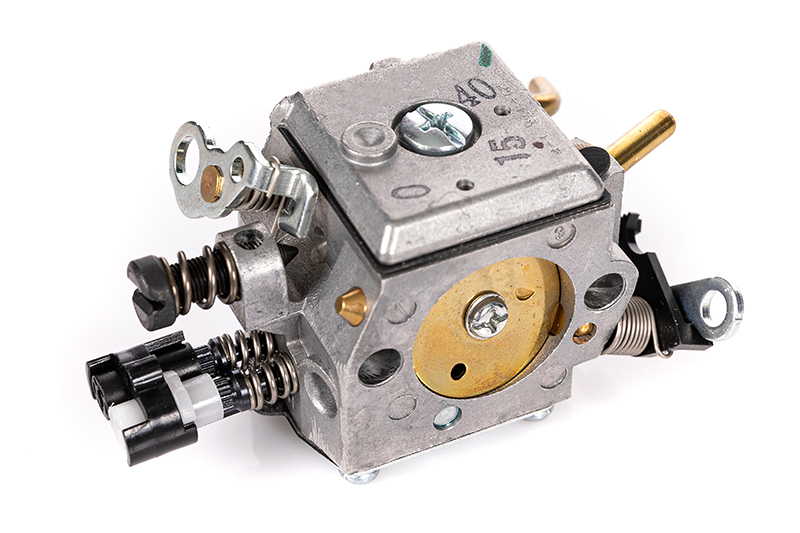

Go kart carburetor

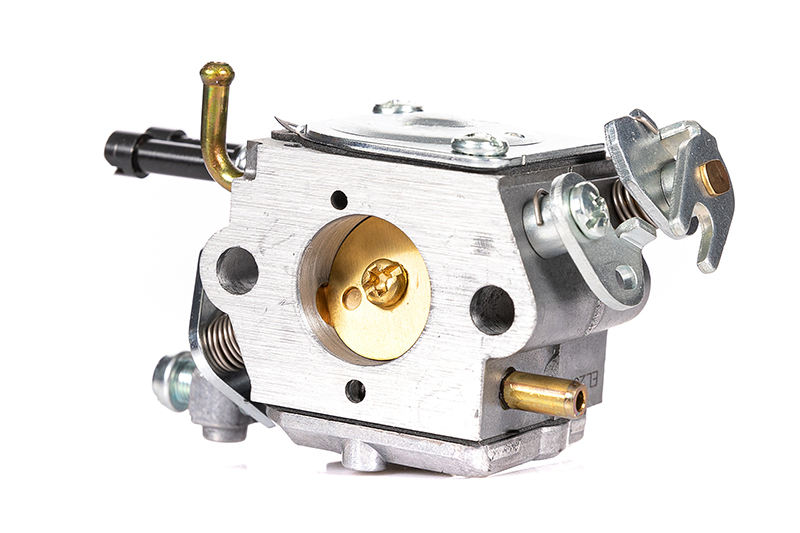

Carburetor components

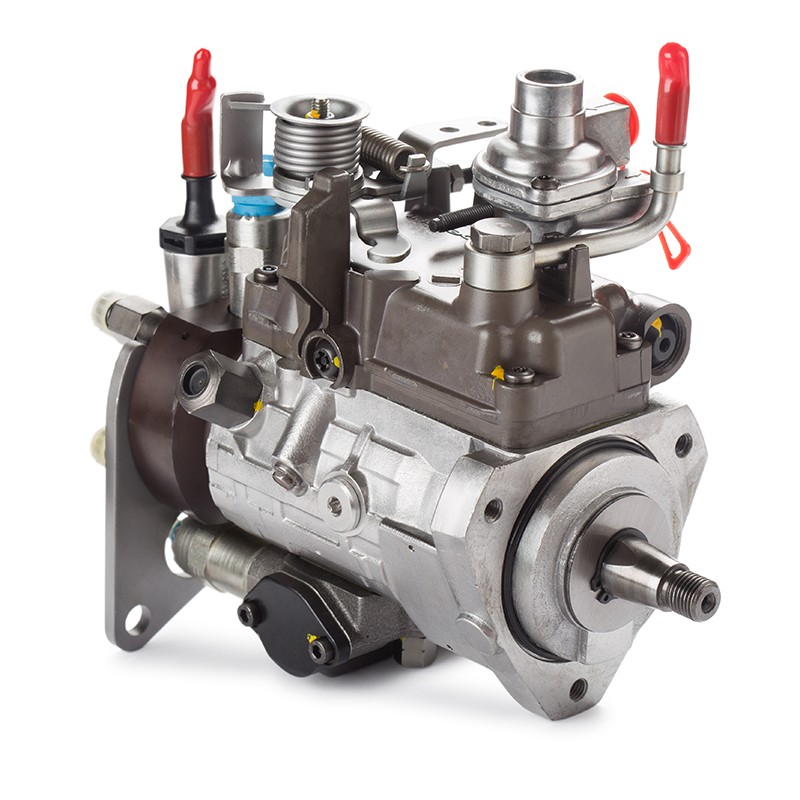

Snow blower carburetor

Contact Info

Mr. Brook Lin

Job Title: Sales manager

E-mail: [email protected]

Mob/WhatsApp:+86 13599927066

Wechat:+86 13599927066 Skype:+86 13599927066

Country/Region: China (Mainland) Province/State: Fujian

Operational Address: Building 172, Tongan Industrial Zone, Tongan Area, Xiamen, Fujian, China (Mainland) Zip: 361100