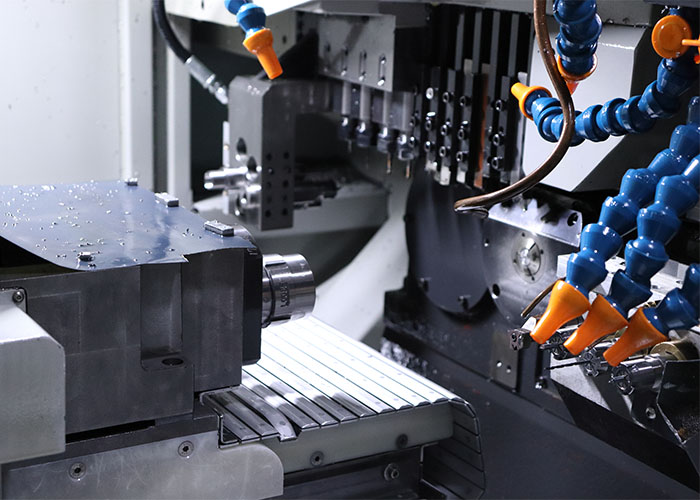

In the world of mechanical machining, each part carries the heartbeat of industrial machinery, silently driving technological progress. As the industry continues to evolve, the precision requirements for mechanical components are becoming increasingly stringent, with fatigue life emerging as a focal point for manufacturers and engineers. In this intricate world, multiaxial fatigue criteria serve as a wise advisor, helping us foresee crack initiation and propagation under complex stress conditions. By taking proactive measures, we can optimize processes and extend the service life of these components. This article explores the practical application of multiaxial fatigue criteria in precision mechanical parts machining, with insights from real-world gear machining cases to provide valuable perspectives for the manufacturing industry.

1. Basic Principles and Application Background of Multiaxial Fatigue Criteria

1.1 Definition and Influencing Factors of Multiaxial Fatigue

In the mechanical world, components endure forces from various directions, forces that alternate like waves crashing against a rock, gradually eroding its surface over time. The damage under these alternating stresses is referred to as multiaxial fatigue. It acts as a silent killer of mechanical part longevity, often causing failure without warning. Understanding its definition and influencing factors is fundamental to building precise machining processes.

1.2 Theoretical Foundation of Dang Van Fatigue Criterion

The Dang Van fatigue criterion serves as a beacon in the field of fatigue life, guiding us in predicting crack initiation in materials under complex stress conditions. It sees fatigue failure as a microscopic battle within the grains of the material, where fatigue cracks begin internally and eventually surface after numerous stress cycles. This criterion allows us to more accurately predict the fatigue life of parts subjected to multiaxial stress.

1.3 Importance of Multiaxial Fatigue Criteria in Mechanical Parts Machining

In the field of mechanical parts machining, multiaxial fatigue criteria act like a wise observer, enabling us to see through complex stress fields and understand how fatigue cracks initiate. Its importance lies not only in predicting fatigue life but also in optimizing machining processes so that parts can perform reliably under harsh conditions.

For example, in China's aerospace manufacturing industry, multiaxial fatigue criteria have been fully applied to the manufacturing of turbine blades for aircraft engines. As these blades endure high temperatures and complex alternating stress, combining multiaxial fatigue criteria with finite element analysis (FEA) allows engineers to precisely predict crack initiation points under thermal stress, optimizing surface treatment processes to extend fatigue life. Similarly, Boeing applies this criterion to predict fatigue life and improve structural components like landing gears and wings.

2. Multiaxial Fatigue Analysis in Gear Machining

2.1 Causes of Gear Contact Fatigue Failure

Gears, the heart of industrial machines, transfer power day in and day out. However, prolonged alternating loads lead to crack formation on the gear surface, ultimately causing fatigue failure. The causes of contact fatigue are not just material properties but also the accumulation of microscopic stresses on the surface during gear meshing. It’s akin to a rope that eventually snaps from overbearing pressure.

2.2 Application of Multiaxial Fatigue Criteria in Gear Machining

In gear machining, multiaxial fatigue criteria are like an experienced doctor diagnosing fatigue risks under alternating stress.

For example, in China's wind power industry, the gearbox is a critical component of wind turbines, and gears need to withstand long-term alternating stress from wind. By integrating multiaxial fatigue criteria, a prominent domestic wind power equipment manufacturer used FEA models to optimize gear manufacturing processes and extend service life. In Europe, SEW-EURODRIVE, a renowned transmission systems manufacturer, employed multiaxial fatigue criteria in the design of industrial gears to accurately predict the initiation of fatigue cracks. By improving heat treatment and surface treatment processes, the company significantly increased gear fatigue life.

2.3 Optimizing Gear Life with Machining Processes: Carburizing, Grinding, and Shot Peening

Like a meticulously crafted artwork, the extension of gear life hinges on optimizing the machining process. Carburizing forms a tough protective layer on the gear surface, while grinding, like an artist finely sculpting a statue, ensures precision in gear meshing. Shot peening acts as an invisible armor, introducing compressive residual stress to enhance fatigue resistance. These processes combined greatly extend the gear's service life.

3. Practical Application of Multiaxial Fatigue Criteria in Mechanical Parts Machining

3.1 Fatigue Life Evaluation of Mechanical Parts Under Complex Stress Fields

The lifespan of mechanical parts is like the smooth ticking of a clock's gears, requiring precise measurement and prediction. In complex stress fields, multiaxial fatigue criteria, much like a microscope, reveal early-stage crack initiation inside components, providing us with accurate fatigue life assessments. This prediction is not only a theoretical derivation but also serves as a safeguard for ensuring quality in actual production.

To better understand how different materials perform under complex stress fields, the table below summarizes the fatigue life assessment of a mechanical part under varying stress levels for three common materials:

| Material Type | Load Type | Stress Level (MPa) | Fatigue Life (Cycles) | Failure Mode |

|---|---|---|---|---|

| Alloy Steel | Multiaxial | 500 | 1,000,000 | Surface Cracks |

| Aluminum Alloy | Uniaxial | 300 | 500,000 | Brittle Fracture |

| Stainless Steel | Multiaxial | 600 | 1,500,000 | Internal Cracks |

As shown in the table, alloy steel and stainless steel exhibit longer fatigue lives under multiaxial alternating stress, while aluminum alloy has a shorter fatigue life under uniaxial stress. These data provide engineers with a basis for material selection and, through multiaxial fatigue criteria analysis, highlight the failure modes and fatigue performance of different materials under complex stress. Thus, selecting the right materials and combining them with multiaxial fatigue criteria can significantly enhance part durability and reliability.

3.2 Influence of Precision Machining Processes on Fatigue Life

3.2.1 The Role of Residual Stress Treatment in Part Machining

Residual stress acts as a "second life" for components, granting them enduring fatigue resistance during machining. By controlling residual stress effectively, we can form a protective barrier on the surface of parts, reducing the likelihood of crack initiation. This process is essential for improving fatigue life, especially in high-load mechanical components.

3.2.2 Impact of Surface Treatments (Shot Peening, Carburizing) on Fatigue

Surface treatments are like armor for components, allowing them to endure fatigue challenges with tenacity. Shot peening introduces compressive stress that reduces stress concentrations, while carburizing hardens the surface, improving fatigue resistance. The combination of both ensures that parts maintain high performance even under complex stress conditions.

3.2.3 The Application of Multiaxial Fatigue Testing Combined with Finite Element Analysis

When multiaxial fatigue criteria are combined with finite element analysis, they form the "golden duo" for fatigue life prediction.

For example, in China's rail transportation industry, the gearbox system in high-speed trains requires extreme durability. By combining multiaxial fatigue criteria with FEA, engineers accurately predict fatigue crack initiation in rail vehicle gears and take preemptive repair measures to prevent in-service failure. In Europe, the TGV high-speed train project in France also utilized this method. By analyzing the stress conditions on the gears, engineers optimized the material selection and surface treatment processes, ensuring the reliability of the gears during high-speed operations.

3.3 Common Fatigue Crack Detection Methods for Mechanical Parts

Detecting fatigue cracks is like tracking down hidden enemies. Early-stage cracks are often invisible to the naked eye, but they are crucial to the longevity of parts. With non-destructive testing techniques, we can detect these cracks early, allowing for repairs before they escalate, ensuring the safe operation of mechanical equipment.

4. Strategies for Improving Fatigue Life in Mechanical Parts Machining

4.1 Optimizing Machining Processes: Reducing Fatigue Crack Initiation

Optimizing machining processes is like injecting "longevity genes" into components. By minimizing stress concentration points during machining and avoiding unnecessary surface damage, the likelihood of crack initiation is significantly reduced. These preventive measures are key to ensuring that mechanical parts remain durable under extreme conditions.

4.2 Design and Manufacturing Improvements Based on Multiaxial Fatigue Criteria

Applying multiaxial fatigue criteria to design and manufacturing is akin to drawing a "health map" for components, guiding us to design durable products. From material selection to process improvement, multiaxial fatigue criteria offer comprehensive guidance, ensuring that parts maintain long-term service life under complex stress conditions.

4.3 Future Trends and Challenges in Fatigue Life Prediction

In the future, fatigue life prediction technology will become more intelligent and precise. With the integration of artificial intelligence and big data analysis, fatigue life prediction will act like an "X-ray," allowing us to fully anticipate component lifespan before production. However, challenges remain in simulating complex stress fields and accurately predicting crack propagation. Continued innovation and research will be the key to advancing the precision of fatigue life prediction in the mechanical machining industry.

The multiaxial fatigue criterion opens a window into the fatigue life of mechanical parts, allowing us to see how components behave under complex stress conditions. This not only helps us better understand failure mechanisms but also provides us with precise tools to optimize machining processes and improve part durability. As we continue to pursue precision and reliability, multiaxial fatigue criteria will remain indispensable in mechanical machining, guiding us forward in the quest for superior performance and longevity. This is not just technological progress but our relentless pursuit of excellence.