Custom CNC Machined Parts | Fast Turnaround and High Accuracy

Key Attribute

Overview

CNC Machining Services for Precision Plastic and Metal Parts

Looking for reliable CNC machining services for your plastic and metal components?

Our expert team offers end-to-end solutions, from design and prototyping to full-scale production.

We specialize in delivering on-demand, high-precision parts tailored to your specifications.

Let our professionals help you turn your vision into reality with fast, efficient, and cost-effective CNC machining services.

Comprehensive Strength

Services | Our company offers a comprehensive range of production services, specializing in precision CNC machining, milling, turning, and metal stamping. Our advanced CNC capabilities ensure high-accuracy and quality. |

Capabilities | We provide custom-machined parts tailored to various industries, using a wide variety of materials, including metals, plastics, and composites. Our surface finishing options enhance durability and aesthetics. |

Equipment List | Our facility is equipped with state-of-the-art CNC machines, including 3-axis and 5-axis mills, lathes, and automated systems designed for high-precision work. |

Industries Served | We serve diverse industries, including aerospace, automotive, medical, electronics, and consumer products. Our expertise helps meet the specific needs of each sector. |

Applications | Our precision machining services are used in a wide range of applications, from automotive components to medical devices and electronics. We ensure each project meets the highest standards. |

Quality Management | Our company is committed to maintaining the highest standards of quality through strict quality control processes and continuous improvements in our systems and techniques. |

| Inspection Equipment | We utilize advanced inspection equipment, including CMM (Coordinate Measuring Machines) and vision systems, to ensure the precision of every part we manufacture. |

| Certifications | We hold various industry certifications, ensuring that our products meet rigorous standards. Our certifications include ISO 9001 and AS9100, demonstrating our commitment to quality and excellence. |

| Mission & Values | Our mission is to provide top-notch machining solutions that meet the needs of industries worldwide. We value integrity, innovation, and customer satisfaction, which drive our operations. |

| Our Vision | We envision becoming the global leader in precision machining, known for delivering cutting-edge technology and unmatched customer service. |

Our Advantage

Attention to Detail

We prioritize precision and thoroughness in every aspect of our machining process to ensure the highest level of quality.

Customer-Focused Approach

Our business is centered around understanding and meeting the unique needs of each client, ensuring their complete satisfaction.

Commitment to Quality

We consistently maintain stringent quality control standards, ensuring reliable and high-performance products every time.

Experienced and Skilled Team

Our team has extensive knowledge and experience in various manufacturing technologies.

Product descriptions

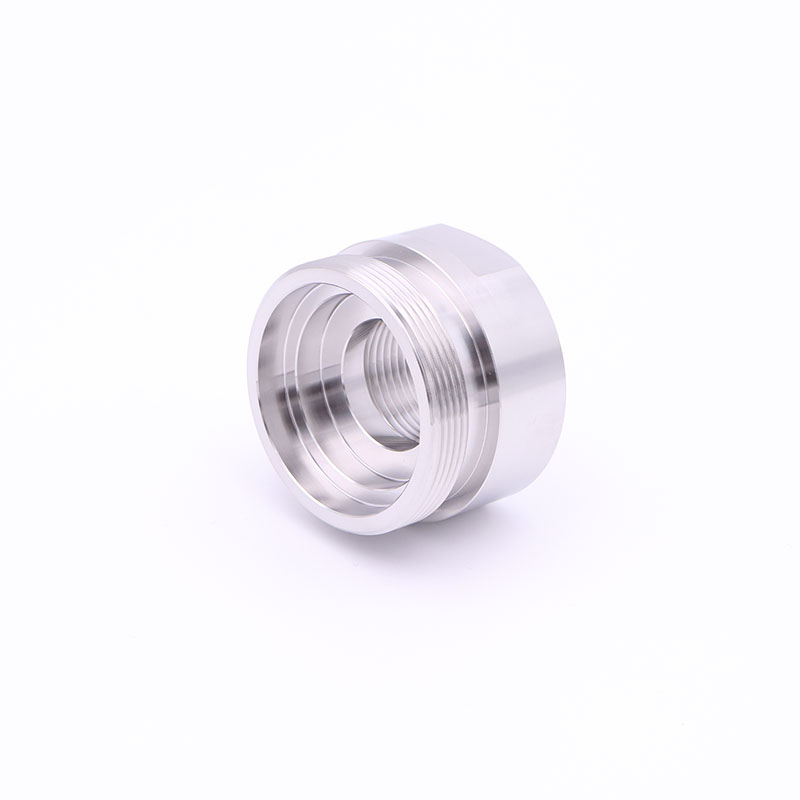

Computer Numerical Control (CNC) machining is a manufacturing process where pre-programmed computer software controls the movement of tools and machinery to shape, cut, and finish materials. Unlike traditional manual machining, CNC machining offers precision, efficiency, and automation in manufacturing complex parts. This technology is essential for producing high-quality, repeatable, and intricate parts across a range of industries.

CNC machining is indispensable in many industries, such as:

Aerospace: CNC machining is used for producing aircraft parts, including turbine blades, structural components, and engine parts. Precision is crucial here to meet strict safety standards.

Automotive: In the automotive sector, CNC machining is used for manufacturing engine parts, gears, and suspension systems. It ensures parts are made to the highest specifications for performance and durability.

Medical Devices: CNC machines help produce surgical instruments, implants, and prosthetics, where precision and hygiene are critical for patient safety.

Electronics: CNC machining is employed in making housings, connectors, and other delicate parts that require exact dimensions.

Defense: CNC machining is used for high-tolerance military equipment and components, offering both performance and reliability in critical applications.

Energy: Components for renewable energy systems, such as wind turbines, solar panels, and power generators, benefit from CNC’s precision and durability.

CNC machining can be applied to various materials, each suited to different applications:

Aluminum: Common in aerospace, automotive, and medical device manufacturing, aluminum is lightweight, durable, and corrosion-resistant, making it ideal for parts subject to extreme conditions.

Stainless Steel: Known for its strength and resistance to rust, stainless steel is used for medical equipment, aerospace components, and machinery requiring high strength.

Titanium: A high-performance material ideal for the aerospace and defense sectors, titanium offers strength and resistance to high temperatures.

Plastic: Versatile and lightweight, CNC-machined plastics are used in consumer electronics, automotive interiors, and medical devices.

Copper: Primarily used in electrical components and heat exchangers due to its excellent electrical conductivity.

At Xiamen Prime KunWu , we specialize in custom CNC machining that caters to specific customer needs. Our team’s expertise ensures that each part meets your exact requirements, whether you need high-precision or complex shapes. By using advanced CNC equipment, we can produce tailored parts with minimal lead time and exceptional accuracy, reducing the need for post-production work and cutting down overall production costs.

The production process begins with CAD design, followed by CAM programming to ensure the machine's precision. Our high-tech CNC mills, lathes, and routers are employed to precisely carve, drill, and cut materials based on the 3D designs. Depending on the complexity of the part, processes like milling, turning, grinding, and EDM (Electrical Discharge Machining) are used.

CNC machining faces challenges such as tool wear, material hardness, and part complexity. We overcome these by regularly maintaining equipment, using cutting-edge tools, and employing advanced software to optimize tool paths. Our team’s experience ensures we can handle even the most intricate designs with ease.

We adhere to strict quality control standards, guided by industry certifications like ISO 9001:2015, to ensure consistency and reliability. From initial inspection to final testing, every part undergoes rigorous checks to guarantee it meets the highest standards.

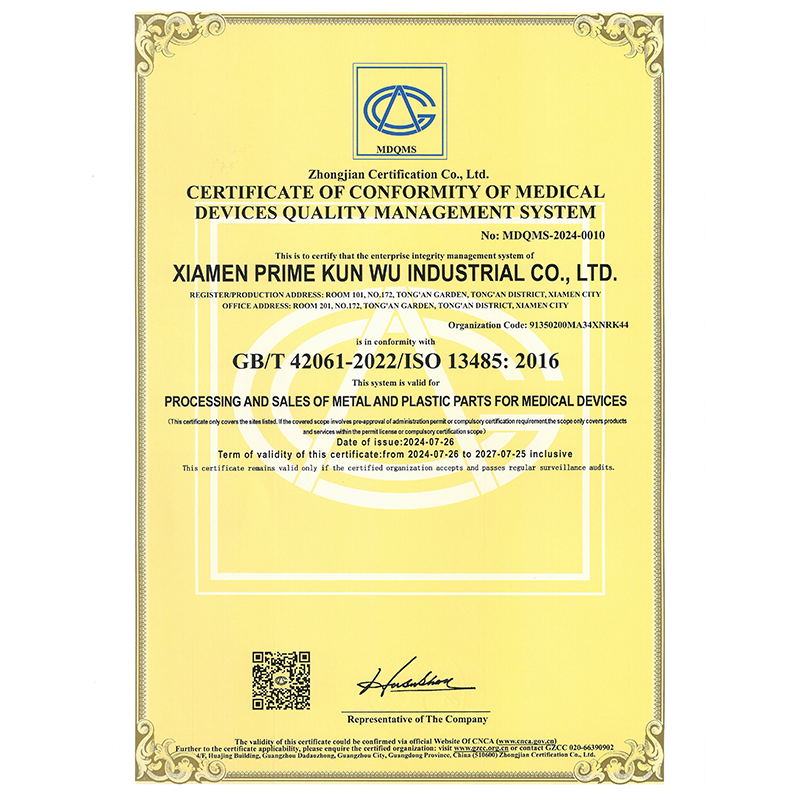

Certifications

| Certifications | GB/T19001-2016/ISO9001:2015 Certification,GB/T 42061-2022/ISO13485:2016 Certification, IATF 16949:2016 Certification |

IATF 16949:2016

GB/T19001-2016/ISO9001:2015

GB/T 42061-2022/ISO13485:2016

Customer Reviews

David Thompson, Senior Engineer, GreenEnergy Co. (USA)

"We faced some manufacturing challenges with critical components for our wind turbines. The complexity of the parts, combined with the need for high material integrity, made us look for a trusted CNC machining partner. Xiamen Prime KunWu exceeded our expectations by providing innovative solutions that addressed both design and material challenges. Their technical expertise and precision helped us achieve production goals on time and with enhanced durability."

Emily Johnson, Product Manager, AutoInnovations Ltd. (UK)

"At AutoInnovations, we required CNC machining for a series of custom components that were crucial for our vehicle's performance. The team at KunWu not only adapted to our complex design needs but also provided insightful recommendations that helped optimize the components for durability and performance. The machining was flawless, and their customer service was second to none – always available to answer our questions and ensure smooth communication throughout the project."

FAQs

1. What is Computer Numerical Control (CNC) machining?

CNC machining is a process where computer software controls machinery to precisely cut, shape, and finish materials, offering high accuracy and automation.

2. What industries use CNC machining?

CNC machining is widely used in aerospace, automotive, medical devices, electronics, and energy sectors, offering precise parts for diverse applications.

3. What materials can be used in CNC machining?

CNC machining works with various materials including metals like aluminum, steel, titanium, and plastics, suited for applications in different industries.

4. What are the advantages of CNC machining?

CNC machining offers high precision, repeatability, and efficiency, reducing errors and increasing production speed compared to manual machining.

5. How do I choose the right CNC machining service?

Choose a CNC machining service based on expertise, quality control, material handling, and the ability to meet your specific design and production needs.

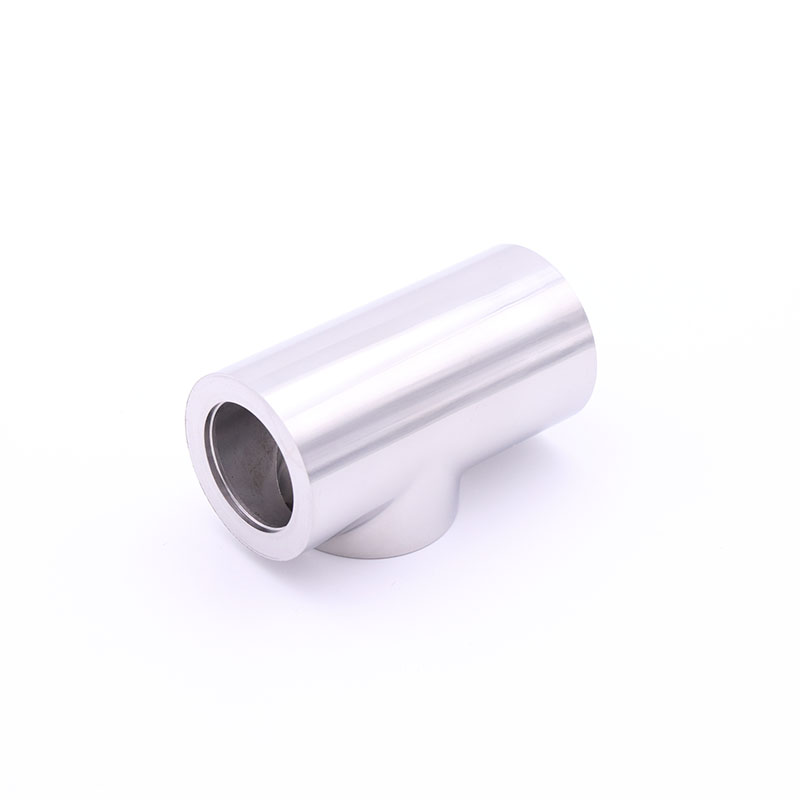

Gallery

3D CNC machining

5 axis cnc machining

CNC machining china

CNC machining pay

CNC machining service

CNC machining services

CNC machining shop

CNC machining shops near me

Contact Info

Mr. Brook Lin

Job Title: Sales manager

E-mail: [email protected]

Mob/WhatsApp:+86 13599927066

Wechat:+86 13599927066 Skype:+86 13599927066

Country/Region: China (Mainland) Province/State: Fujian

Operational Address: Building 172, Tongan Industrial Zone, Tongan Area, Xiamen, Fujian, China (Mainland) Zip: 361100