Introduction

In the fast-paced world of mechanical processing, the need for precision, speed, and efficiency is paramount. Industries relying on machining often encounter challenges when it comes to the precise positioning and angle fixing of products. Traditional jigs may lack flexibility, require prolonged setup times, or fail to deliver the necessary precision for complex tasks. Addressing these challenges, Xiamen Prime Kunwu Industrial Co., Ltd. proudly introduces an innovative solution in the form of our patented Quick Angle Fixing Jig. This practical tool has been specifically designed to revolutionize the process of angle fixation in mechanical applications, ensuring quicker setups, higher accuracy, and increased productivity.

Understanding the Technology Behind the Quick Angle Fixing Jig

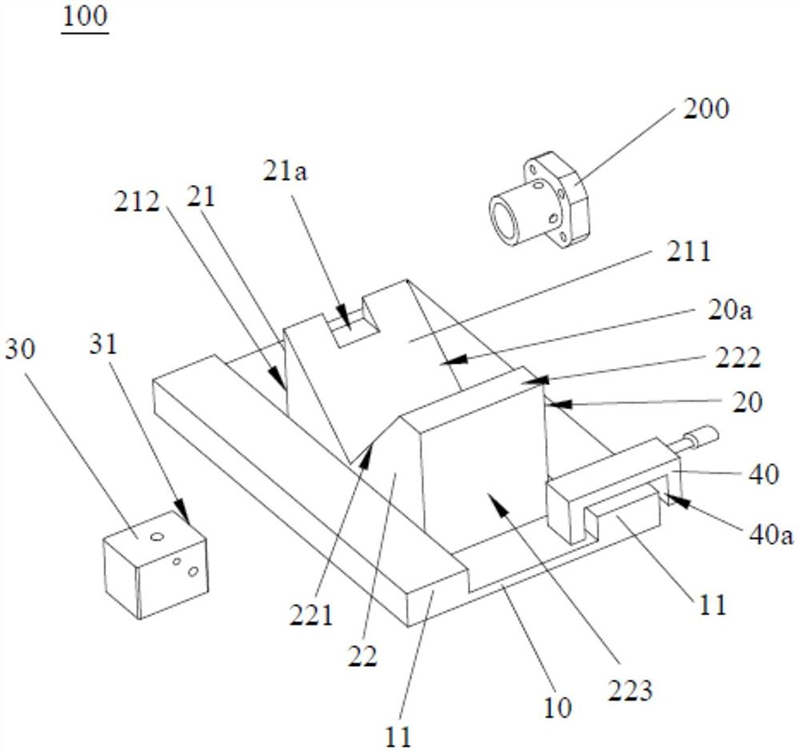

At the core of the Quick Angle Fixing Jig lies a straightforward yet highly effective principle — enabling fast and secure product positioning at fixed angles. The jig consists of three primary components: the base, the positioning seat, and the top component. Together, these elements allow for quick adjustments and precise angle control without the need for complex setup procedures.

Key Components & Operation

Base: The base of the jig features two parallel positioning strips that are designed to create a stable and secure foundation for the jig. These strips serve as a guide, ensuring that products are accurately placed between them.

Positioning Seat: The positioning seat sits between the two positioning strips and is equipped with two raised sections that include inclined surfaces. These surfaces form a space that precisely fixes the product's angle when placed in the jig. The key to the jig's innovation lies in the arrangement of these surfaces, which allows for a quick and secure angle setting.

Top Component: The top component is positioned on the seating and includes angled sidewalls that are designed to match the inclination of the positioning seat. These sidewalls ensure that the product stays securely in place during machining. This alignment minimizes errors and reduces the need for constant adjustments, improving efficiency in production.

Innovative Features and Benefits

The Quick Angle Fixing Jig introduces several innovative features that distinguish it from traditional fixtures:

Rapid Angle Fixing: The specially designed inclined surfaces form an accurate fixed space that allows for quick angle setting, ensuring minimal downtime during machining processes.

Adjustable Components: The jig includes a sliding seat that can be adjusted along the positioning strips, allowing users to fine-tune the positioning according to the size and angle requirements of the product.

Precision and Stability: The top component’s angled sidewalls ensure that the product remains firmly fixed, providing consistent results across multiple machining operations.

Ease of Use: The design is straightforward, allowing operators to set the jig quickly without the need for intricate setups or constant repositioning, enhancing overall productivity.

Additional Features:

The positioning seat may include a notch that allows for additional alignment precision.

The jig’s design accommodates a variety of products, from smaller precision components to larger industrial parts.

Applications of the Quick Angle Fixing Jig

The Quick Angle Fixing Jig has wide-ranging applications across several industries that rely on mechanical processing. Some of the most notable applications include:

Precision Machining: The jig is ideal for use in CNC (computer numerical control) machining, where precise and rapid positioning is crucial to achieving high-quality results.

Assembly Line Operations: For industries such as automotive manufacturing, the jig can be used to ensure that components are placed at the exact angles needed for automated assembly processes.

Custom Manufacturing: In sectors where bespoke parts are produced, the jig offers the flexibility needed to handle varying product specifications and angles.

Tooling and Mold Manufacturing: The jig’s robust design makes it suitable for the demanding environment of tooling and mold manufacturing, where accuracy is essential.

By integrating this jig into the workflow, businesses can reduce setup time, increase repeatability, and ultimately improve the quality of the final product.

Future Developments and Applications

Looking ahead, the Quick Angle Fixing Jig is poised for further development and innovation. Potential improvements could include:

Smart Integration: Future iterations of the jig may incorporate sensors or digital interfaces to allow for real-time monitoring and automated adjustments, making it an even more powerful tool in precision machining.

Material Improvements: With ongoing advancements in materials science, the jig could be developed using lighter yet stronger materials, further enhancing its durability and adaptability across industries.

Broader Industry Applications: While the jig is currently used primarily in machining and assembly, there are opportunities for expansion into other sectors such as electronics assembly, aerospace manufacturing, and even in the medical device industry, where precision is critical.

Conclusion

The Quick Angle Fixing Jig represents a significant leap forward in mechanical processing technology. Designed with simplicity, efficiency, and precision in mind, it addresses the key challenges faced by industries requiring quick and accurate angle fixing. By integrating this innovative tool into your workflow, your company can achieve higher efficiency, reduced downtime, and improved product quality — all while maintaining cost-effective operations. As industries continue to evolve, this jig will remain a crucial asset, paving the way for new developments and applications in the world of precision machining.

FAQs

1. What is a Quick Angle Fixing Jig?

A Quick Angle Fixing Jig is a tool designed for quickly and precisely setting angles in mechanical processing, improving efficiency in machining tasks.

2. How does the Quick Angle Fixing Jig improve precision machining?

By providing a fixed, adjustable angle positioning system, it ensures accurate product placement, reducing errors during machining.

3. What are the benefits of using a Quick Angle Fixing Jig in manufacturing?

It minimizes setup time, enhances machining accuracy, and ensures product consistency, especially in high-volume production lines.

4. Can the Quick Angle Fixing Jig be used in CNC machining?

Yes, it is ideal for CNC machining, where precise angle fixation is crucial for high-quality results in automated processes.

5. What industries benefit from the Quick Angle Fixing Jig?

Industries like automotive, tooling, and electronics manufacturing can significantly improve their precision and efficiency with this jig.