Introduction:

In today’s advanced manufacturing industry, precision and efficiency are key drivers for improving production quality and reducing costs. As robots become more integrated into industrial processes, the need for specialized equipment that can handle the unique demands of robotic arm shell production is more critical than ever. Traditional bending equipment often struggles with consistent positioning and stability when processing sheet metal, especially for complex geometries like robotic arm shells. Xiamen Prime Kunwu Industrial Co., Ltd. has developed an innovative solution—a cutting-edge bending machine that significantly enhances accuracy, efficiency, and operational ease.

Technological Innovation:

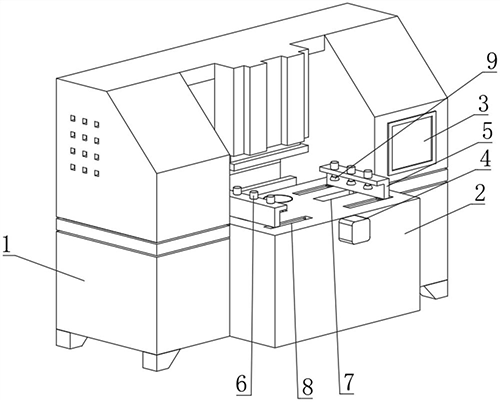

The new bending equipment introduced by Xiamen Prime Kunwu features a combination of mechanical and electrical systems designed to optimize the sheet metal forming process. One of the primary innovations lies in the advanced control and positioning mechanisms, which include a specially designed worktable equipped with a sliding groove and an adjustable moving groove. These features are combined with a servo motor and threaded rods to ensure precise and synchronized movement during bending.

By using servo motors to rotate connecting shafts, which in turn drive gears and threaded rods, the equipment achieves simultaneous, oppositely directed rotation of two threaded rods. This design significantly improves the stability and consistency of the fixture during bending. The synchronized movement of the sliding block and fixed plate, along with a telescoping rod with a fixed suction cup, ensures that sheet metal is securely held in place, preventing shifts and ensuring precise bending. This system addresses the common issue of sheet metal displacement, which is critical in producing high-quality robotic arm shells.

Technological Realization:

The equipment consists of several key components:

Worktable: The surface of the worktable is equipped with a sliding groove, which facilitates the smooth movement of the fixed plate.

Servo Motor and Threaded Rods: A servo motor drives a rotating connecting shaft, which in turn powers the two threaded rods. The synchronization between the rods ensures stable and precise movement of the metal sheet.

Telescopic Rod and Suction Cup: These components allow for the vertical fixation of sheets of varying thicknesses, further ensuring the integrity of the bending process.

Fixed Plate and Sliding Block: The fixed plate is designed to slide along the grooves, while the sliding block interacts with the threaded rods to facilitate synchronized movement.

This design minimizes human error, reduces setup time, and ensures that each piece of sheet metal is securely held, minimizing the risk of distortion during the bending process.

Comparison with Traditional Technologies:

Unlike traditional bending systems, which often rely on manual adjustments and basic mechanical components, this new system leverages automation and precise control mechanisms to enhance accuracy. In traditional systems, sheet metal can often slip or shift during the bending process, especially with thicker or irregularly shaped sheets. This patent solves these issues by incorporating synchronized movements and adjustable fixtures, leading to a dramatic reduction in production errors and improved consistency.

Furthermore, the servo motor-driven threaded rods provide an automatic and continuous adjustment mechanism, eliminating the need for manual recalibration. This reduces labor costs and accelerates production timelines, offering significant advantages over conventional equipment.

Applications and Future Prospects:

This bending equipment is ideal for industries where precision sheet metal forming is essential, such as in the manufacturing of robotic arms, automotive parts, and aerospace components. With the increasing demand for robots in industrial automation, the potential applications for this technology are vast. The equipment could also be adapted for use in industries such as electronics and consumer goods, where complex sheet metal forming is required.

Looking ahead, the development of this bending technology opens the door to further innovation in automated manufacturing. Future enhancements could include integration with AI-powered predictive maintenance systems and the ability to handle a broader range of materials and thicknesses, further enhancing the machine's versatility and performance.

Conclusion:

The innovative bending equipment from Xiamen Prime Kunwu Industrial Co., Ltd. addresses significant challenges in the robotic arm shell fabrication process. By improving the accuracy, efficiency, and flexibility of sheet metal bending, this technology provides manufacturers with a reliable solution to enhance production quality while reducing operational costs. With its wide-ranging applications and potential for future enhancements, this technology is poised to drive significant advancements in the sheet metal fabrication industry.

FAQs

What is the main advantage of using bending equipment for robotic arm shell fabrication?

The bending equipment enhances precision, reduces errors, and ensures consistent sheet metal fixation, improving overall efficiency and quality.How does this bending equipment improve sheet metal forming compared to traditional methods?

It uses synchronized servo motor-driven threaded rods for precise and stable sheet metal holding, reducing manual adjustments and production errors.What industries can benefit from robotic arm shell bending equipment?

This equipment is ideal for industries like robotics, automotive, aerospace, and electronics, where precise sheet metal fabrication is crucial.Why is robotic arm shell bending equipment more reliable than manual processes?

The automated system minimizes human error, ensures consistent sheet positioning, and speeds up production by using mechanical precision and servo control.How does this bending equipment handle different sheet metal thicknesses?

It features a telescoping rod with a suction cup, providing adjustable vertical fixation for different sheet thicknesses, ensuring stable and accurate bending.

Contact Info

Mr. Brook Lin

Job Title: Sales manager

E-mail: [email protected]

Mob/WhatsApp:+86 13599927066

Wechat:+86 13599927066 Skype:+86 13599927066

Country/Region: China (Mainland) Province/State: Fujian

Operational Address: Building 172, Tongan Industrial Zone, Tongan Area, Xiamen, Fujian, China (Mainland) Zip: 361100