Introduction:

In the rapidly advancing world of electronics, efficient thermal management plays a critical role in ensuring the longevity, performance, and reliability of devices. Traditional cooling methods, often relying on passive heat sinks or external fans, frequently fail to meet the demanding requirements of modern, compact devices like cameras. This limitation has sparked the need for innovative solutions. At Xiamen Prime Kunwu Industrial Co., Ltd., we are proud to introduce an innovative heat dissipation structure for camera housings, a breakthrough that not only enhances thermal performance but also contributes to a more efficient and sustainable design. This article delves into the core technology, innovation, and practical application of our patented design.

Technological Innovation:

Our patented heat dissipation structure stands apart from conventional solutions by incorporating an active, gear-driven fan mechanism. Unlike traditional passive systems that rely solely on heat sinks or externally mounted fans, our design integrates the cooling system directly into the camera housing. The central innovation lies in the combination of a motor-driven gear system and movable fan blades, which actively regulate airflow and heat distribution.

Key Benefits over Existing Solutions:

Enhanced Cooling Efficiency: Traditional cooling solutions struggle with limited airflow, often leaving hot spots within the camera body. By introducing a motorized mechanism, our design ensures a dynamic cooling process, directing airflow to critical areas and improving overall thermal management.

Cost and Space Efficiency: Our design reduces the need for additional external cooling components, which can be bulky and costly. By integrating the cooling system within the camera housing, we provide a compact, cost-effective solution suitable for space-constrained devices.

Reliability: Conventional cooling systems, particularly those relying on static parts, often fail over time due to wear and tear. Our design reduces the chances of component failure by incorporating robust, active systems that allow for better adaptability to changing thermal conditions.

Comparison with Traditional Technology:

Existing camera cooling technologies rely primarily on passive methods such as heat sinks, or the use of external fans mounted on the device. While these solutions can dissipate heat, they are limited in their ability to efficiently manage heat in compact environments like camera bodies. Moreover, external fans can add bulk, increase power consumption, and require more maintenance.

Our patented design overcomes these limitations. By incorporating a driven motor connected to a gear system inside the housing, we ensure that the cooling fan operates dynamically. This fan rotation, powered by the motor, promotes airflow in multiple directions, allowing for better heat dissipation across the entire camera body. Moreover, the system actively adjusts, improving efficiency under various operating conditions.

Technology Implementation:

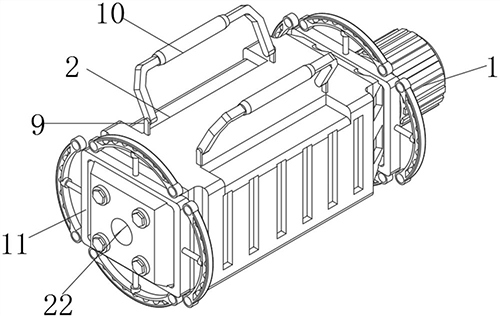

At the heart of the design is the integration of several components:

Camera Body and Housing: The camera’s outer casing is integrated with a heat dissipation plate that conducts heat away from the sensitive internal components.

Drive Motor and Gear Mechanism: A motor is installed inside the housing, and its output is connected to a gear system, which in turn drives a rotating fan. This fan actively distributes the heat away from the camera components.

Fan Blades and Airflow Regulation: The blades are configured to rotate dynamically, allowing for a constant adjustment of airflow to critical areas of the camera body.

In terms of manufacturing, the key to implementing this technology lies in precision engineering. The housing must be designed to house the motor and gear system while ensuring that the fan blades are positioned correctly for optimal airflow. This requires an advanced understanding of mechanical design principles, thermodynamics, and manufacturing processes.

Application Prospects:

The practical applications of this innovative heat dissipation design extend beyond cameras. While initially developed for consumer electronics, such as security cameras and digital cameras, the technology can easily be adapted for use in other small form-factor electronics where thermal management is critical. This includes drones, smartphones, and wearable devices, all of which generate significant amounts of heat in compact enclosures.

The technology has immense market potential, especially as electronics become increasingly smaller and more powerful. As we look to the future, we foresee this technology being integrated into OEM parts for a wide range of consumer products, revolutionizing the way we manage heat in compact electronics.

Conclusion:

Our patented camera housing heat dissipation structure offers a significant leap forward in the way we approach thermal management in compact devices. The integration of active cooling components, such as a motor-driven fan system, improves cooling efficiency, reduces costs, and enhances the reliability of electronic devices. As the demand for smaller, more powerful electronics grows, this technology holds great promise for a wide range of applications. At Xiamen Prime Kunwu Industrial Co., Ltd., we are excited to be at the forefront of this technological revolution, driving innovations that will shape the future of consumer electronics.

FAQs

1. What is the importance of heat dissipation in compact electronics?

Efficient heat dissipation is crucial for preventing overheating, ensuring the longevity and performance of compact electronics like cameras and smartphones.

2. How does the new camera housing heat dissipation system work?

The system uses a motor-driven gear mechanism to actively rotate a fan, improving airflow and distributing heat more effectively within the camera housing.

3. What makes this heat dissipation design more efficient than traditional methods?

Unlike passive systems, the motor-driven fan actively adjusts airflow, ensuring better thermal management and reducing the need for external components.

4. Can this innovative heat dissipation technology be used in other electronics?

Yes, it can be adapted for various compact electronics like OEM parts in drones, wearable devices, and smartphones, where efficient thermal management is critical.

5. How does this technology improve the cost-effectiveness of electronic devices?

By integrating the cooling system directly into the camera housing, it eliminates the need for bulky external components, reducing overall manufacturing costs.

Contact Info

Mr. Brook Lin

Job Title: Sales manager

E-mail: [email protected]

Mob/WhatsApp:+86 13599927066

Wechat:+86 13599927066 Skype:+86 13599927066

Country/Region: China (Mainland) Province/State: Fujian

Operational Address: Building 172, Tongan Industrial Zone, Tongan Area, Xiamen, Fujian, China (Mainland) Zip: 361100