Introduction

In the automotive manufacturing industry, precision and efficiency are paramount in the production of essential car parts. The rear upper control arm, a crucial suspension component, requires highly accurate and reliable manufacturing processes to ensure the safety and performance of vehicles. Traditional clamping and processing fixtures often fall short in terms of efficiency, stability, and production speed, creating a demand for innovative solutions in this area. At Xiamen Prime Kunwu Industrial Co., Ltd., we have developed an innovative solution in the form of our patented Dual-Link Processing Fixture for Rear Upper Control Arms. This invention promises to revolutionize the manufacturing process by significantly enhancing clamping speed, improving fixture stability, and reducing production time.

Technical Principles and Innovations

Basic Technical Principles

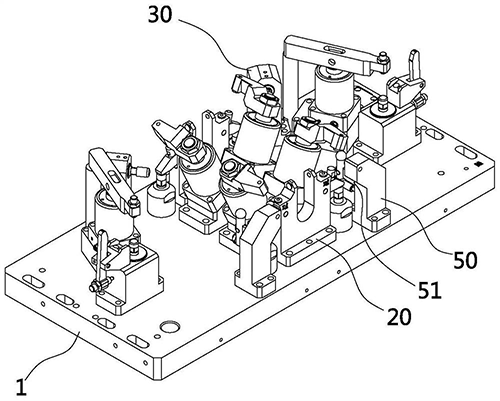

The core concept behind this invention lies in utilizing a dual-link fixture design that allows for the simultaneous clamping of two rear upper control arms. The fixture consists of several key components: a large-hole channel installation plate, first and second clamping assemblies, and pneumatic cylinders for precise control. The integration of pneumatic drives ensures efficient positioning and clamping, reducing manual errors and ensuring consistent quality across mass production runs.

Core Innovations

Dual-Link Clamping System: The fixture features two independent clamping assemblies mounted on a common large-hole channel installation plate. This allows for the processing of two rear upper control arms simultaneously, increasing throughput and reducing downtime between operations.

Pneumatic Cylinder Integration: The fixture uses advanced pneumatic systems to control both the positioning and clamping of components. With dedicated pathways for pneumatic cylinders, including drive, unloading, and clamping channels, this design ensures seamless automation and reduces human intervention, leading to higher precision and faster cycle times.

Modular Design for Flexibility: The fixture's design is modular, with individual components such as the clamping assemblies being easily replaceable. This adaptability allows for quick changes between different control arm designs, making it suitable for a variety of production needs.

Compact and Stable Structure: The fixture is compact yet highly stable, designed to withstand the mechanical stresses associated with high-speed production environments. This results in a robust solution that minimizes vibrations and potential misalignments during the clamping process.

Applications and Case Studies

The Dual-Link Processing Fixture is ideally suited for high-volume production lines where speed, precision, and stability are critical. Below are some examples of its application in real-world scenarios:

Automotive Assembly Lines: In large-scale car manufacturing, the fixture can be used to clamp and process rear upper control arms for various vehicle models. By enabling the simultaneous processing of two control arms, manufacturers can significantly reduce cycle times and improve the overall efficiency of the production line.

Custom and Aftermarket Production: The modular design of the fixture allows for quick adjustments to accommodate different types of control arms, making it ideal for aftermarket parts manufacturers who require flexibility in their production processes.

High-Precision Prototyping: In rapid prototyping environments, the fixture can be employed for the quick and accurate production of control arm prototypes. The ability to clamp and process two pieces at once increases the speed of prototype development, reducing the time required to bring new designs to market.

Future Outlook and Conclusion

The Dual-Link Processing Fixture for Rear Upper Control Arms not only solves the challenges faced by traditional clamping systems but also presents a versatile solution for future applications in automotive manufacturing. As production demands evolve, this fixture's flexibility and efficiency will become increasingly valuable. The potential for expanding its use in other areas of automotive part manufacturing or even in other industries, such as aerospace or heavy machinery, is vast.

Xiamen Prime Kunwu Industrial Co., Ltd. is committed to continually advancing our solutions to meet the ever-changing needs of the industry. We believe that this invention marks just the beginning of our journey to enhance the manufacturing processes that power the automotive industry.

FAQs

1. What is a Dual-Link Processing Fixture in automotive manufacturing?

The Dual-Link Processing Fixture is an innovative tool that enables the simultaneous clamping and processing of two rear upper control arms, boosting efficiency and precision.

2. How does the pneumatic system in this fixture work?

The pneumatic system uses separate pathways for driving, unloading, and clamping operations, ensuring accurate, automated positioning with minimal manual intervention.

3. Why is the dual-link structure essential for car part manufacturing?

The dual-link design reduces setup time, improves stability, and allows for high-speed production, essential for mass manufacturing of car parts like control arms.

4. Can this fixture be adapted for other car components?

Yes, the modular design allows adjustments to accommodate various car components, making it versatile for diverse production needs, including prototypes.

5. What industries could benefit from this fixture besides automotive?

This fixture is also applicable in aerospace, heavy machinery, and rapid prototyping industries, where precision and efficiency are critical.

Contact Info

Mr. Brook Lin

Job Title: Sales manager

E-mail: [email protected]

Mob/WhatsApp:+86 13599927066

Wechat:+86 13599927066 Skype:+86 13599927066

Country/Region: China (Mainland) Province/State: Fujian

Operational Address: Building 172, Tongan Industrial Zone, Tongan Area, Xiamen, Fujian, China (Mainland) Zip: 361100