Introduction:

In the rapidly advancing field of precision machining, achieving efficient, reliable, and cost-effective solutions for component clamping is essential. Many industries, from automotive to aerospace, rely heavily on the precision of their clamping systems to ensure seamless production processes. However, existing clamping technologies often face challenges, such as limited stroke adjustment, inconsistent performance, and a lack of versatility in accommodating different component sizes. This is where the Lever Cylinder Assembly for Clamping, developed by Xiamen Prime Kunwu Industrial Co., Ltd., revolutionizes the industry by introducing a versatile, reliable, and efficient solution to tackle these issues head-on.

Core Technology and Principles:

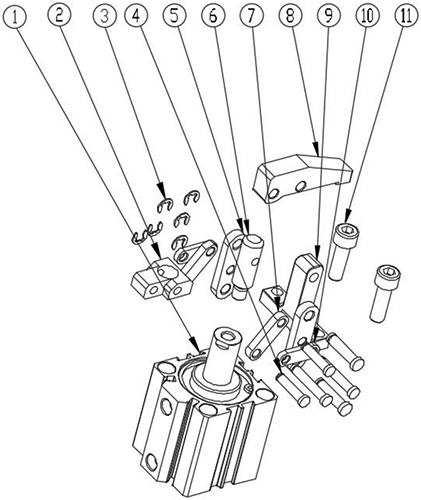

At its core, this invention offers a lever cylinder assembly that utilizes a unique design to improve the efficiency of clamping operations. The assembly consists of a cylinder body, a push rod, connecting blocks, and several movable chains. These components work together to facilitate precise movement and control of the clamping head, which is crucial for holding objects in place during machining operations.

One of the most remarkable aspects of this design is its innovative stroke adjustment mechanism. Traditional clamping cylinders often suffer from fixed stroke lengths that restrict flexibility, especially when handling parts of varying sizes. This invention overcomes that limitation by enabling the clamping head to adjust its stroke dynamically. The result is a system that can accommodate a broader range of workpieces while maintaining high precision.

Innovative Features and Design:

Dynamic Stroke Adjustment: The cylinder's stroke is controlled via a set of edge chains that allow for adjustable movement of the clamping head. The push rod located at the top of the cylinder body moves the connecting block, which in turn drives the movement of the clamping head. This mechanism ensures the clamping head has greater flexibility in its stroke, making it adaptable for different part sizes and machining operations.

Increased Precision: The assembly's design minimizes errors in part alignment by utilizing a precise combination of chains, push rods, and support structures. This results in improved clamping accuracy and better consistency across multiple machining cycles.

Simplified Construction: Unlike traditional systems that rely on complex, intricate components, this design uses straightforward components that are easy to assemble and maintain, significantly reducing operational downtime and maintenance costs.

Applications and Benefits:

This lever cylinder assembly is perfect for industries that require high-precision clamping, such as machined parts manufacturing, automotive assembly, and aerospace production. Some key applications include:

Machining Operations: During CNC machining, the system allows for dynamic adjustments to the clamping stroke, ensuring workpieces are held securely at optimal positions without restricting movement.

Tooling and Fixtures: The versatility of this assembly makes it an ideal solution for tooling fixtures, where the ability to change clamping pressures and adjust stroke lengths enhances the machining process.

Automated Production Lines: In automated systems, where consistency and reliability are key, this clamping solution provides better control over part positioning, ensuring that components are held securely, allowing for high-volume production.

Prototype Development: For industries focused on prototype development, the ability to adjust clamping forces and stroke lengths ensures that even delicate parts can be securely clamped without risking damage.

Future Prospects:

Looking ahead, this lever cylinder assembly has immense potential for further development. Its adjustable stroke mechanism could be further enhanced with smart sensors and controls, allowing for automated adjustments based on the size and material properties of the workpiece. Additionally, the integration of IoT (Internet of Things) technology could facilitate real-time monitoring and adjustment in manufacturing environments, offering unprecedented precision and flexibility in precision machining.

Conclusion:

Xiamen Prime Kunwu Industrial Co., Ltd.'s Lever Cylinder Assembly for Clamping represents a significant step forward in mechanical processing technology. By addressing the limitations of traditional clamping systems and offering an adaptable, efficient solution, this invention is set to become a game-changer in the machining industry. As it continues to evolve, the potential applications and innovations driven by this design will likely shape the future of precision machining for years to come.

FAQs

What is the function of a lever cylinder assembly in precision machining?

The lever cylinder assembly provides dynamic stroke adjustment, improving precision and flexibility in clamping during CNC machining operations.

How does the lever cylinder assembly improve clamping precision?

It ensures secure positioning of workpieces by using chains, push rods, and a supporting structure, minimizing alignment errors and enhancing accuracy.

What industries benefit from using the lever cylinder assembly for clamping?

It is ideal for industries like automotive, aerospace, and mechanical processing that require high-precision clamping for machining and assembly.

How does the lever cylinder assembly compare to traditional clamping systems?

Unlike traditional systems, it offers adjustable stroke length, allowing for more versatile clamping of different workpieces and greater operational flexibility.

Can the lever cylinder assembly be integrated into automated production lines?

Yes, its precise control and adaptability make it perfect for integration into automated production lines, improving efficiency and reducing downtime.

Contact Info

Mr. Brook Lin

Job Title: Sales manager

E-mail: [email protected]

Mob/WhatsApp:+86 13599927066

Wechat:+86 13599927066 Skype:+86 13599927066

Country/Region: China (Mainland) Province/State: Fujian

Operational Address: Building 172, Tongan Industrial Zone, Tongan Area, Xiamen, Fujian, China (Mainland) Zip: 361100