Project Brief

Industry | Medical Robotics |

| Product | Machining of Exoskeleton Robot Components |

Challenges | Precision requirements, material specialization, complexity in machining, dynamic load stress |

Technology | Multi-axis CNC machining, advanced surface treatments |

Material | High-performance alloys (strength and fatigue-resistant) |

Surface finish | Coating, wear-resistant finishes |

Quantity | Custom, based on project needs |

Lead Time | Reduced by 15% using optimized workflows |

Client Requirement Overview

The client operates in the medical industry, specifically focusing on the development of exoskeleton robots designed to enhance mobility and support for individuals with disabilities or physical impairments. Their primary need was to source high-precision machined components that could meet strict design and functional requirements for their robotic systems. The components needed to exhibit exceptional strength, durability, and exact specifications, making this project a technically challenging undertaking.

With the rise of technological advancements in the healthcare sector, the demand for highly sophisticated robotic devices continues to increase. However, these innovations often face significant technical hurdles, including maintaining accuracy at micro-scale levels and ensuring component reliability under constant mechanical stress. The client was looking for a machining partner with the expertise to deliver custom solutions while meeting these stringent demands.

Project Description

The project focused on machining complex exoskeleton robot components that required both fine-tuned precision and robustness. The parts were to be incorporated into a fully functional exoskeleton, which demands perfect alignment and exceptional durability, particularly under dynamic load conditions. The initial technical challenge involved working with high-strength materials that require specialized machining techniques to achieve the necessary precision.

The project’s goal was clear: to provide a customized, reliable solution that could meet the exacting specifications and high-performance demands of the client’s robotic exoskeleton system.

Solution and Implementation Process

To address the unique challenges of this project, Xiamen Prime Kunwu Industrial Co., Ltd. employed a series of advanced machining technologies tailored to meet the client’s needs.

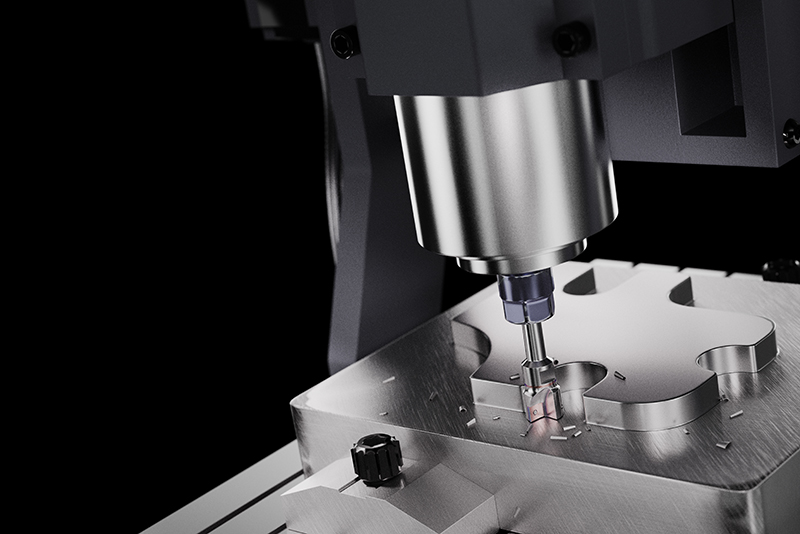

Advanced Multi-Axis Machining: The parts required machining on multiple axes to achieve the precise geometry needed for integration into the robotic system. This required the use of state-of-the-art CNC machining centers equipped with 5-axis capabilities to handle the complex shapes of the components.

Material Selection and Specialization: The parts were made from high-performance alloys known for their strength and fatigue resistance, critical for exoskeleton applications. Special care was taken in material selection to ensure both durability and machinability.

Quality Control: Rigorous quality control measures were implemented throughout the machining process to ensure all components met the exact tolerances specified. This included precision measurements and testing using coordinate measuring machines (CMM) to ensure dimensional accuracy.

Innovative Surface Treatments: To enhance wear resistance and longevity, the components underwent advanced surface treatments, including coating and finishing processes that improved their performance in high-stress conditions.

Results and Outcomes

The project delivered several key outcomes, which were critical for the client’s ongoing development of exoskeleton robots:

Improved Production Speed: By utilizing advanced manufacturing technologies and optimized workflows, the project’s lead time was reduced by 15%, accelerating the delivery of components.

Enhanced Precision: The CNC machining process ensured that all components met the precise specifications required by the client, achieving an impressive tolerance of ±0.01mm.

Cost Optimization: Through efficient use of resources and material selection, the overall cost of production was optimized without compromising the quality of the components.

The final product was delivered on time, meeting all quality standards and exceeding the client’s expectations for performance and durability.

Customer Feedback

— John Smith, CTO, RoboExos

“Xiamen Prime Kunwu Industrial Co., Ltd. provided an exceptional solution for our exoskeleton robot components. Their precision machining capabilities and commitment to quality ensured that we received the high-performance parts necessary for our project. We were particularly impressed with their ability to meet our tight timelines while delivering exceptional quality. We look forward to continuing our partnership with them.”

Conclusion and Call to Action

This project highlights Xiamen Prime Kunwu Industrial Co., Ltd.’s ability to tackle complex technical challenges in the medical and robotics industries. By leveraging advanced machining technologies and a customer-first approach, the company delivered a tailored solution that met the client’s precise requirements.

If you face similar technical challenges in your industry, we are here to help. Contact us today to discuss how we can deliver high-precision solutions for your most demanding projects.